BY SOMA MEDICAL (SM) IN AFFILIATION WITH IAQ DIAGNOSTICS (ID)

We provide advanced robotic solutions that cater to various types of industries and their processes.

YOUR DATA CENTRE IS AT THE HEART OF YOUR BUSINESS. KEEP IT HEALTHY!

Data Centres and Computer rooms mainly house rows of racks containing an assortment of business critical equipment. Dust and contamination will cause extreme problems if not correctly addressed. All accessible surfaces of equipment are vacuumed using triple stage filtration equipment and wiped where necessary with anti-static cloths. Clean dust free fans and vents will help reduce power consumption and also help address cooling issues.

Data Centres and Computer rooms are often designed to suit each customer's individual requirements, therefore making each room and environment unique. Our approach to the cleaning operation is to treat every environment on an individual basis. Regular cleaning schedule will be a major step towards protecting and ensuring the smooth efficient operation of your systems.

OUT OF SIGHT IS NOT OUT OF MIND

WHAT DOESN'T KILL YOU, IF LET BE, WILL EVENTUALLY!

Foul smelling odours are caused by a mixture of chemicals released from proteins, bacteria and organic matter and if left untreated they will multiply and spread further. This leads to the odour intensifying making it increasingly difficult to contain and eliminate. Environments such as factories, houses, retail outlets, commercial premises, healthcare establishments and food preparation areas can all suffer from problems with malodours. Offensive smells are not only off-putting for your employees they are also unpleasant for your customers. Failure to remove unpleasant odours can have a negative effect on productivity, profitability and the reputation of your business. Our removal service provides a rapid and cost effective solution for areas suffering from foul smelling odours. We identify the source of offensive odours and quickly and efficiently neutralises and eradicates the pungent smell leaving a fresh and clean smelling environment.REDEFINING GRAVITY

Dust and other contamination accumulate on the surfaces of HVAC system during its construction and operation. HVAC systems should be cleaned at regular intervals, especially if the system conveys very combustible material such as grease or organic dust. The national regulations and guidelines give time periods to inspect cleanliness of HVAC system, limit values for dust accumulation and time periods to clean HVAC system. The aim of this study was to develop a verifying concept to control and verify the cleanliness of HVAC systems.

Contaminations and their measuring methods. MICROBE CONTAMINATIONS

The contact method and the swapping method were studied to measure the microbe concentrations

on the duct surface. The laboratory and field studies showed that the microbial concentrations

measured with the contact method were lower than with the swab method. The upper

detection limit of the contact method was 5–10 CFU/cm2.

MINERAL FIBRES

Two tape sampling methods, the gelatine and the carbon tape, were studied to measure mineral

fibre contamination on ventilation ductworks. The samples were collected from the duct surfaces

and analysed with an optical and a scanning electron microscope (SEM). The gelatine tape was found to be suitable for light microscopic analyses and it allows counting the fibres on the surface. The carbon tape was

applicable to SEM analyses and the method allowed the analysis of the chemical composition of fibres. The mean fibre concentration of the studied HVAC system was 112 fibres/cm2 (11–1490 fibres/cm2) measured with the gelatine tape.

VISUAL EVALUATION

The visual evaluation method with a visual cleanliness scale and an visual inspection form has been designed to use it as a primary method to evaluate the cleanliness of HVAC system. A robot with a video camera is used to reach the visual inspection into the whole ductwork.

.

DUST AND GREASE

A simple comb method (Figure 1) was developed to evaluate the thickness of dust and debris layer on the duct surface.

The developed comb and the deposit thickness test (D.T.T.) method introduced in the British guideline (Figure 2) were tested in the laboratory and in the field.

The results of the deposit thickness methods were compared with the vacuum test method (Figure 3). The laboratory tests showed that the dust accumulation measured with the comb method correlated with the vacuum test method (R2= 0.5–0.9) when the dust layer was homogeneous. However, no correlation was found when dust accumulation was heterogeneous.

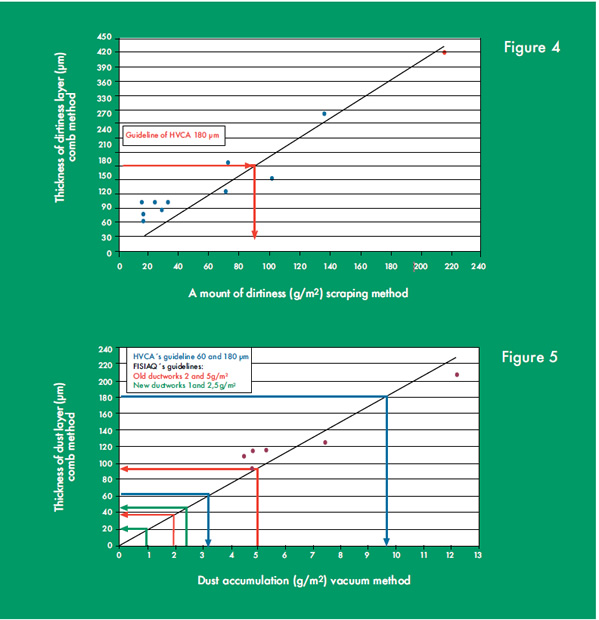

In the field test, the mean amount of the grease layer varied between 34–142 g/m2 measured with the vacuum test method and 0.1–1 mm measured with a comb method. The correlation between the comb and the vacuum test method (Figure 4) and between the D.T.T. and the vacuum test method (Figure 5) was 0.84 and 0.9, respectively.

CONCLUSION

A visual cleanliness scale, a visual inspection form and a simple deposite thickness comb have been developed for the systematic visual evaluation of the cleanliness of air ducts. A robot video camera is used to reach the visual inspection into the whole ductwork. The amount of dust and debris is measured with the vacuum test method and the thickness of the grease layer with the D.T.T. method if the cleanliness level of the ducts is not clear enough visually. The microbial contamination will be measured with the contact method and the fibre contamination with the tape sampling method.